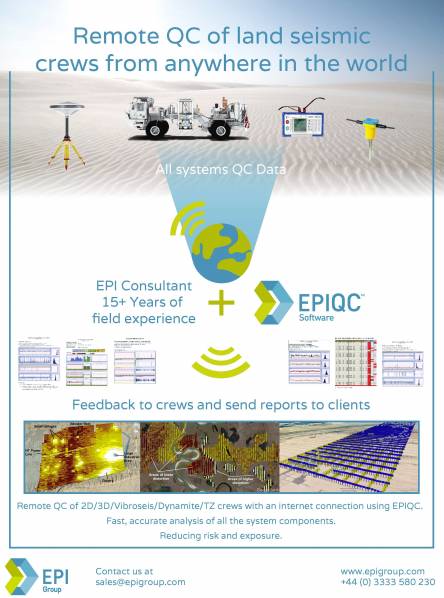

EPI Remote Land Seismic QC Launches

We are pleased to launch our remote land seismic QC service, enabling the remote QC of 2D/ 3D/ Vibroseis/ Dynamite/ TZ crews with an internet connection, using our proprietary software – EPIQC.

We reduce the risk and exposure of having more people in the field, whilst maintaining quality acquisition.

Our recent client, Nestor Sanabria of Repsol, had this to say:

“Repsol has been using the EPIQC program to monitor and QC the performance of vibrators during the survey we are acquiring currently in the North Slope, Alaska. The programa has shown to be efficient for a first fast analysis of vibe performance by using the pss files form the recorder. Pss files provide average and peak information for vibrator performance attributes such as harmonic distortion, phase and force. The EPIQC software provides a detailed daily report with performance charts per vibe and attribute, kmz maps and listings that include out of spec sweeps. Having the report available once the data is provided to our infield QC’s it has been a valuable tool for an early identification of vibrators incurring in a higher percentage of errors, which help to mitigate the risk of having broken vibrators later. Contractor vibe mechanics have received the advice of our QC’s based on the program analysis to be able to identify problems in the vibes at an early stage.”

“Listings of out specs sweeps from the program are being used to flag sweeps in the AClog to support final processing. The mapping tool is being useful to identify areas with near surface conditions that could affect vibrators performance. Program efficiency and easy visualization displays are an essential component of the software’s functionality which are crucial to deal with an ultrahigh productivity vibroseis crew. The tool is user friendly with an interface that allows the user to define spec tolerances for each attribute. EPI has provided continuous support during the installation and utilization of the program and has allowed direct communication with the software developer which has been very helpful to include additional features to the reports according to our needs.”

“In general, considering the limitations of the information in the pss files, the software has been helpful to optimize the time used to QC the vibrators and to improve the quality of the information that our QC’s provide as feedback to the Contractor. We recommend EPI to implement further analysis to the tool by using the vibrator signals (VSR) to provide additional and specialized analysis of vibrator performance.“