So, what is Seismic QC, and why bother?

The seismic QC Consultant is primarily interested in the quality of the data collected on a survey. This data is not just seismic (in its various UHR, HR, 2D, 3D, OBC, 4D and 4C guises), but navigational, magnetic, gravity, sonar, bathymetric as well as geotechnical and environmental data.

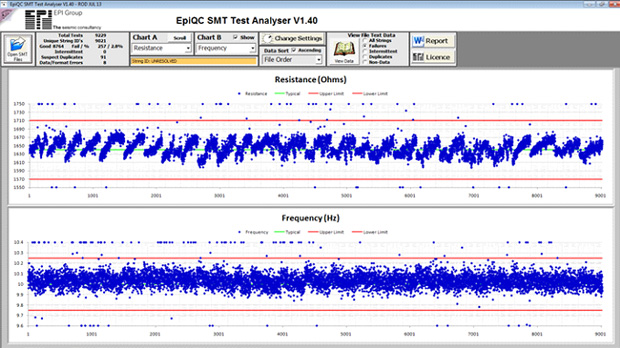

EpiQC Example SMT Analyser

However, the QC is not just responsible for the data. They are also accountable to the client company (which may be several clients in partnership) whom they are representing out in the field; they are the company’s independent ‘man Friday’. It is their job to ensure the survey is conducted safely, timely, efficiently and accurately, whilst at all times acquiring a top quality dataset. Their independence is key, being able to offer objective views and recommendations on the survey and its progress.

The QC must have sound technical knowledge, they need to understand the vast array of marine and land instruments, and be able to tell if they are working correctly or not. Part of the QC’s role is to assess the equipment’s suitability for the survey, and be able to make recommendations for improvements. They need to be able to spot issues with the equipment – this isn’t always picked up (or disclosed) by the contractor. If, for example, one of the vibrator land seismic trucks is giving result which are subtly different from the others, but still within specification, it is the experienced QC who will spot this and investigate why this might be happening.

HSE is another hot topic for the QC; they must be familiar with organisations such as SOLAS and often will have higher HSEQ qualifications such as NEBOSH. The QC must be able to assess if the survey is being carried out in a safe manner. Are the crew using the correct PPE? Does the vessel carry the correct life rafts and safety suits? Are the land explosives being stored in the correct manner? What do you do when you discover deficiencies? It is the experienced QC who can resolve these problems and enable the survey to continue, or indeed put a stop to proceedings with a recommendation that work does not go ahead until the non-conformities are fixed. Are regular drills carried out? Are the crew able and competent enough to be able to tackle a fire in the engine room? It is the QC who needs to assess these questions and be able to make recommendations as necessary.

Diplomacy is a large part of the job. The QC has to act as the go-between for the client (or clients, as is more often the case) and the contractor. When things go wrong, the QC needs to keep a clear head to ensure the best possible outcome is sought in the face of poor quality, unsafe or questionable practises.

As large quantities of data are collected it is the QC that must analyse this to ensure the data is fit for purpose. Analysis must be carried as to whether it is within noise tolerances, within technical specifications, within the correct datum, set at the correct depth – and all in a timely manner. EPI consultants are provided with a suite of tools to QC the data and report back to clients.

In order to assess the data, consultancies use a variety of 3rd party specialist QC software packages, or their own specialist software, such as EPI’s own EpiQC™ for land operations.

Choose Experience – Expect Results